By Mike Busch

For the past twenty years, I’ve been preaching the gospel of reliability-centred maintenance, the then-revolutionary philosophy of maintenance developed in the 1960s at United Airlines by aeronautical engineer Stanley Nowlan and mathematician Howard Heap. Reliability-centred maintenance was almost universally adopted by the airlines in the 1970s, by military aviation in the 1980s, and by high-end business aviation in the 1990s.

The only segment of aviation that hasn’t yet enthusiastically adopted reliability- centred maintenance is owner-flown general aviation. I’ve made it my personal crusade to change this, and to help drag light plane maintenance kicking and screaming into the twenty first century.

Reliability-centred maintenance arose from a rigorous analysis of historical data by Nowlan and Heap showing that the airlines’ maintenance programmes called for more preventive maintenance than necessary, and that such excessive maintenance was actually making aircraft safety and dispatch reliability worse rather than better by increasing the incidence of maintenance induced failures. At the time, these findings were considered heresy by most folks in airline maintenance organisations, who had been taught to believe that maintenance is a good thing and more maintenance is always better. In spite of these objections, the airlines adopted reliability-centred maintenance anyway. Not only did they save a fortune on reduced maintenance costs, but aircraft safety and dispatch reliability improved significantly.

The core principle of reliability-centred maintenance is that most preventive maintenance should be performed only when genuinely necessary. It accomplishes this by doing away with most scheduled preventive maintenance (including most TBOs) and replacing it with a programme of condition-based maintenance. This means doing away with time-based maintenance in favour of a programme of inspections designed to assess the condition of critical aircraft components and to determine when their condition has deteriorated to the point that failure might be imminent. Component repair, overhaul, or replacement is not performed until a condition inspection indicates it is required. As a result, work is performed only when demonstrably necessary, as opposed to at an arbitrary time interval when some aeronautical engineer calculated that it might possibly be necessary.

Reliability-centred maintenance has been a huge step in the right direction, but it’s still less than a perfect solution. It requires regular condition inspections that are not inexpensive and may be somewhat invasive – they involve taking things apart and putting them back together – and so are not completely free of maintenance-induced failure risk. Perhaps we can do even better.

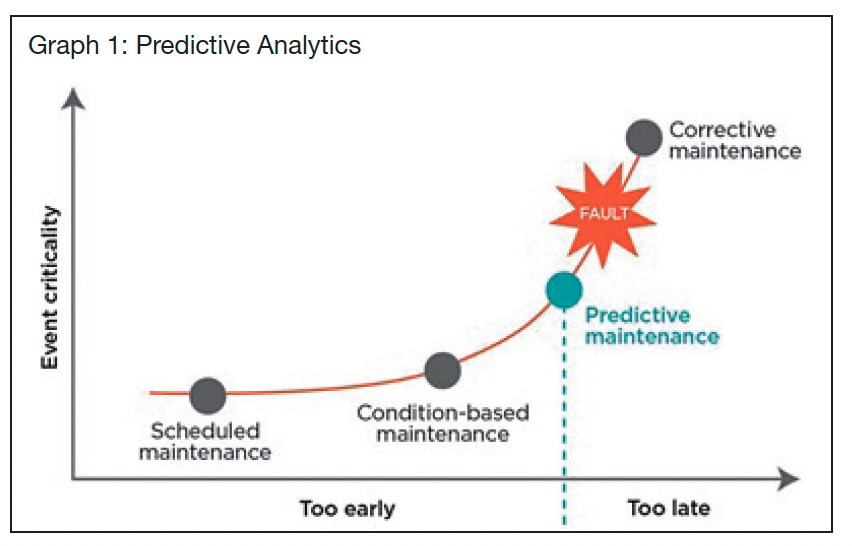

During the two decades I’ve been working to bring the benefits of reliability-centred maintenance to owner-flown GA, another quiet revolution that started with the airlines has been quietly trickling down the aviation food chain. It’s called predictive maintenance and is based on a technology known as predictive analytics. (See graph 1)

Condition-based maintenance has been a huge step forward, compared with traditional scheduled maintenance. Predictive maintenance is the next big step forward. FEVA 2.0 uses machine learning techniques to predict when exhaust valves are at elevated risk of failing. Predictive analytics Modern air transport aircraft and engines are built with thousands of sensors that measure air data, critical engine operating parameters, vibration levels, electrical and hydraulic system parameters, flight control and landing gear positions, fluid levels of all kinds, cabin pressurisation and environmental parameters, and just about every other measurable aspect of the aircraft. Measurements from these many sensors are digitised by the aircraft’s data acquisition unit and then either transmitted to ground stations in real time or captured continuously by a quick-access recorder and extracted once the aircraft is on the ground, via the cellular network or on flash memory cards.

Predictive analytics – also known as predictive failure analysis – employs computer algorithms to process this mass of digital data and detect patterns indicating that some sort of preventive maintenance is necessary, or that evidence of some incipient component failure has been detected. Detection of parameter degradation, exceedance, or adverse trending – low tyre pressure, high electrical bus voltage, decreasing oil pressure – is generally pretty easy. Prediction of ‘rare events’ – contaminated fuel nozzle, damaged compressor blade, failing engine bearing – may require complex algorithms.

Boeing pioneered predictive analytics sixteen years ago when it introduced a service it calls Airplane Health Management (AHM). Boeing’s AHM monitors the health of an aircraft in flight and relays that information in real time to airline personnel on the ground. When the aircraft lands and arrives at the gate, maintenance crews are ready to make any needed repairs quickly. AHM algorithms also attempt to predict when aircraft components are in jeopardy of failing so the operator can replace or repair them at the next scheduled maintenance check.

Nowadays, virtually every airline that flies Boeing’s 777 or 787 uses AHM, and Boeing is working to expand the service to earlier Boeing models as well as to non-Boeing aircraft (eg, intercontinental business jets).

Last year, I had the opportunity to see AHM in action when I visited the Boeing Global Services office in Englewood, Colorado, and to say I was impressed would be an understatement. This is very cool technology. Not to be outdone, Boeing’s arch rival Airbus has launched a predictive analytics service called Skywise in partnership with Palantir Technologies, a Palo Alto, California, software company that specialises in big data analytics.

Recently Airbus announced a partnership with Delta Air Lines as the pilot customer for Skywise Predictive Maintenance on Delta’s A320 and A330 aircraft to assess the failure probabilities of aircraft parts and anticipate the need for preventive maintenance tasks. Delta is claiming a success rate of more than 95 percent for pending failure predictions. According to Delta, the carrier had only 55 maintenance-related flight cancellations in 2018, compared with more than 5,600 cancellations in 2010, and it credits predictive analytics for most of this improvement in dispatch reliability. Jet engine manufacturers also have adopted this technology.

General Electric presently appears to have the lead in predictive analytics with its Prognostic Health Management Plus programme of real-time analysis of continuously downlinked engine operating data for both air carriers and high-end bizjets. Pratt & Whitney’s eFAST has similar objectives, and in 2018 its parent company, United Technologies, acquired Predikto, an Atlantabased provider of predictive analytics software. Rolls-Royce appears to be still developing its predictive analytics programme called IntelligentEngine.

What about piston GA? Few of our piston GA aircraft are riddled with sensors the way modern airliners like the 787 or A330 are. But more than half our fleet is equipped with some sort of digital engine monitor capable of capturing exhaust gas temperatures, cylinder head temperatures, and other engine parameters. Some of these engine monitors also capture fuel flow, air data (altitude, airspeed, outside air temperature), electrical bus data (volts and amps), and/or GPS position. Quite a bit of interesting analysis can be done with this data.

In 2012 my company launched a free web-based digital engine data analysis platform at SavvyAnalysis.com. Since then, owners have uploaded data from more than 10,000 piston GA aircraft to the platform, and our database now contains data from some 2.5 million flights. From inception, this platform has automatically flagged exceedances such as high CHT. In recent years, we’ve been developing and incorporating more sophisticated predictive analytics algorithms. Failing (burned) exhaust valves are ‘rare events’, but they’re the leading cause of cylinder replacement, and exhaust valve failure is a significant cause of piston engine power-loss incidents. I’ve long observed that failing exhaust valves often cause small, slow, rhythmic EGT oscillations that are fairly easy to spot in a graphical plot of the data.

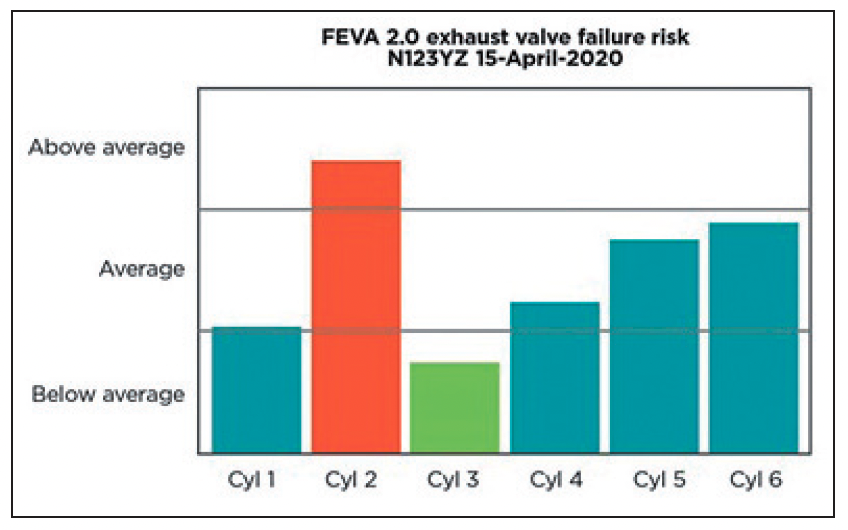

In 2015, we developed a heuristic algorithm called FEVA (Failing Exhaust Valve Analytics) that scans all uploaded engine monitor data for this signature. We’ve been using this to alert owners to the possibility that they may have a failing exhaust valve and that a borescope inspection of the cylinder is suggested. But to be honest, we’ve been less than thrilled about the accuracy of the FEVA algorithm.

Over the past year, we’ve been developing a new algorithm (FEVA 2.0) that uses machine learning techniques, and we’ve trained the algorithm on thousands of flights involving known good and known-failing exhaust valves. The result is a significantly higher accuracy rate and fewer false positives than the heuristic FEVA 1.0. In the meantime, we’ve been working hard to develop another algorithm (SEVA) to detect the sticking exhaust valve syndrome that especially afflicts Lycoming engines and is often referred to as ‘morning sickness’. A sticking exhaust valve typically starts off causing fairly innocuous roughness when the engine is first started cold, and which goes away as the engine warms up. But if not detected and addressed early, a sticking exhaust valve can progress to the point that it results in a bent pushrod and power loss, and occasionally a valve strike and catastrophic engine failure. It’s obviously important to catch this condition early when it’s still in the incipient stage. This seems like a perfect candidate for predictive analytics, and the preliminary results of our R&D have been very encouraging.

Predictive maintenance is clearly the wave of the future. The more sensors we have in our aeroplanes, the more comprehensive and powerful it will become. Over time, it will increasingly be our aircraft – not our mechanics – that tell us what maintenance needs to be done.

This article first appeared in the Autumn 2021 edition of Approach Magazine, the dedicated magazine of AOPA NZ, which is published quarterly.